IBRL provides testing facilities for industrial biotechnology innovations

URBANA, Ill. – Biotechnology is a rapidly growing industry in the United States and worldwide. Consumer demand for renewable products is exploding, while advances in synthetic biology enable efficient production of bio-based ingredients. Some ethanol plants are now retrofitting their facilities to produce high-quality corn sugar products.

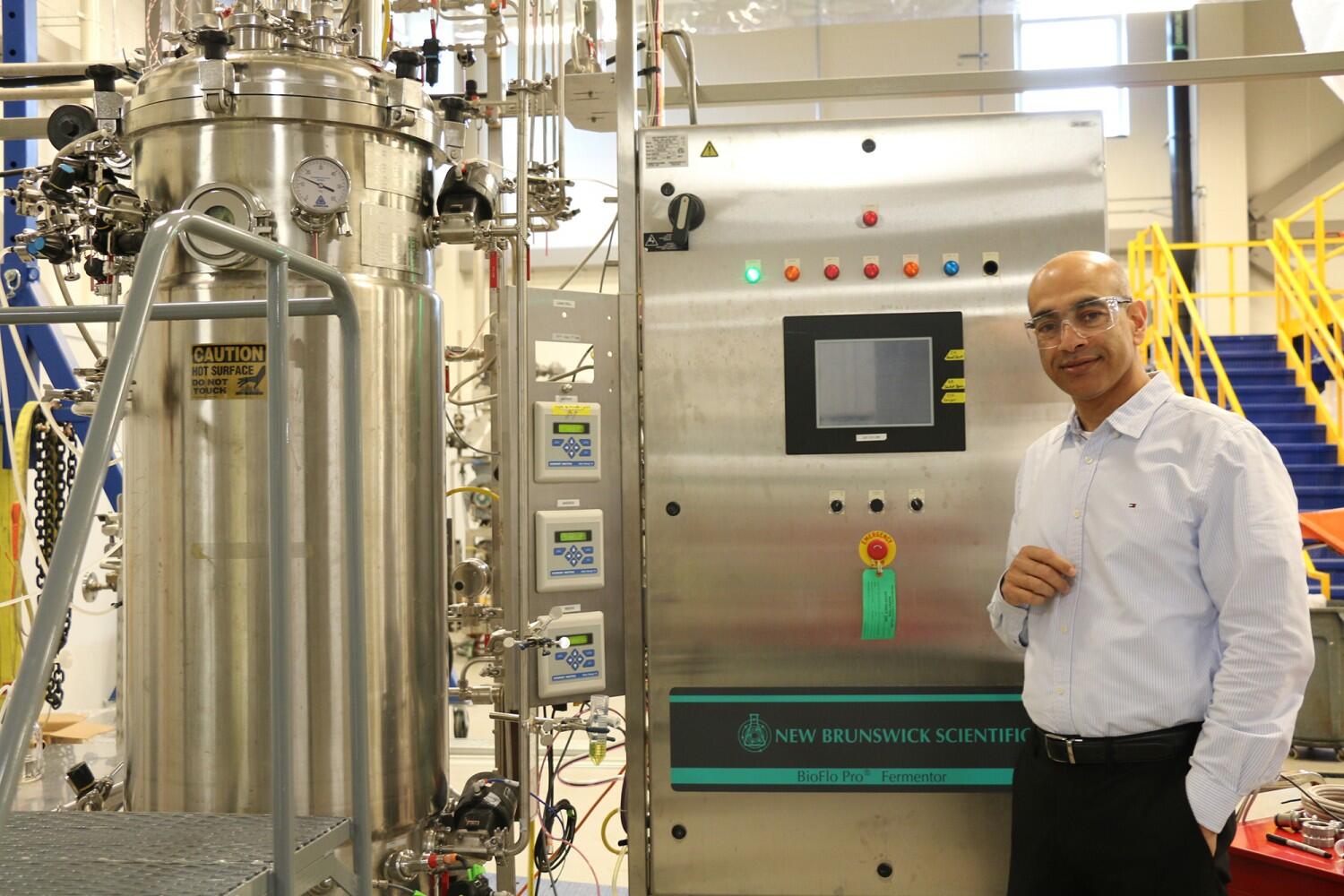

However, converting the technology at a commercial scale can be a risky venture, and companies need help testing their products, says Vijay Singh, professor of agricultural and biological engineering and director of the Integrated Bioprocessing Research Laboratory (IBRL) at the University of Illinois.

“There is a huge need for facilities like IBRL to help grow the biotech industry,” Singh says. “We work with industry partners to de-risk the technology. They can come here and test their innovations at a small scale, then they can evaluate and make changes before moving on to full commercial scale.”

IBRL opened in September 2018, and in its first year it has already hosted more than 50 projects for 20 different companies. Projects include creating alternative proteins, polymers for cosmetics, animal feed, and much more.

Singh discusses biotech trends and industry implications in a recent article published in Cereal Foods World.

“Sustainability is a big trend in consumer products. This has created a market pull and companies are trying to address that by using more renewable materials in their products,” he says. “For example, there’s a car that’s made up of polylactic acid. That means the whole car is made from a plastic that can degrade completely. And shoe companies are making shoes that are 100% biodegradable.”

Another major trend in bioprocessing is plant-based products that replace meat, such as meatless burgers. Feeding a growing world population with meat products is not sustainable, Singh says. The solution may be alternative meat products produced with synthetic biology. “These products taste like meat, smell like meat, cook like meat. And they take a lot less resources to produce than meat,” he explains.

At the same time, consumers are moving away from traditional corn processing products such as high fructose corn syrup. This opens up opportunities for new uses of fermented sugars. Many different products can be made from corn-derived sugars, ranging from biodegradable plastics to cosmetics, cleaners, adhesives, and food products.

Along with higher emphasis on sustainability, advances in industrial biotechnology has made production of specialized fermentation organisms much faster and more affordable.

“We can now put pathways inside the microorganisms that ‘eat’ the sugars and convert the carbon into all kinds of value-added products,” Singh says.

Because of the demand for high-value sugar products, some ethanol plants are looking to change their production capacities. There are about 200 dry-grind facilities in the US that produce about 16 billion gallons of ethanol per year.

“Demand for ethanol is driven by federal mandate so it is dependent on policy,” Singh says.

But the demand for high-quality sugars continues to grow, so dry-grind corn plants are starting to retrofit their facilities to accommodate that market.

However, there are considerable challenges in converting these new opportunities into a commercially viable operation. The ability to test product development in a smaller-scale facility can greatly improve the viability of biotech production, Singh says.

“You need a facility where you can generate products at a smaller scale and test them with consumers. If there are things you need to fix, you can fix it at this scale before moving on to demonstration or full commercial scale,” he says.

“Partnering with university-based facilities that are specifically intended to accelerate commercialization is a very good option,” he suggests. “They have the equipment, trained personnel, and analytical capabilities to serve as pilot plants for companies.”

“IBRL offers one such facility,” Singh concludes.

The article, “Industrial Biotechnology: Shaping Corn Biorefineries of the Future,” is published in Cereal Foods World. [DOI: https://doi.org/10.1094/CFW-64-4-0062]. Authors include Vijay Singh, Joel Stone, Jeffrey P. Robert, and Sundeep N. Vani.

The Department of Agricultural and Biological Engineering and the Integrated Bioprocessing Research Laboratory are in the College of Agricultural, Consumer and Environmental Sciences (ACES) and The Grainger College of Engineering at the University of Illinois.