Pretreatment Methods Bring Second-gen Biofuels from Oilcane Closer to Commercialization

In collaboration with other Bioenergy Research Centers (BRCs), researchers at the Center for Advanced Bioenergy and Bioproducts Innovation (CABBI) are developing industrially feasible techniques for second-generation biofuel production from oilcane, an oil-rich variety of sugarcane, to help meet our growing societal demand for fuels.

In a traditional biorefinery, sugarcane is used as a feedstock to produce bioethanol fuel. These are “first-generation” biofuels – that is, fuels produced from types of biomass that are often used for food and feed. Sugarcane stalks are crushed to extract their juice, and that juice goes on to be processed into fuel. Meanwhile, the dry fibrous material that remains after crushing, a form of lignocellulose, is burned.

However, lignocellulose can also be used to produce “second-generation” biofuels – fuels that come from non-food biomass. Lignocellulose-derived fuels are particularly enticing because they do not compete with food and are suitable for large-scale production of biofuels and bioproducts, as they are widely available in the form of agricultural crop residues.

In a new inter-BRC collaboration, published in Sustainable Energy & Fuels, researchers from CABBI, the Joint BioEnergy Institute (JBEI), and the Great Lakes Bioenergy Research Center (GLBRC) investigated and compared the effects of different pretreatment methods on the oilcane lignocellulose conversion pipeline in terms of lipid recovery, sugar yield, and ethanol yield. Few prior studies have compared the viability of these pretreatment techniques, and none have been performed using oilcane.

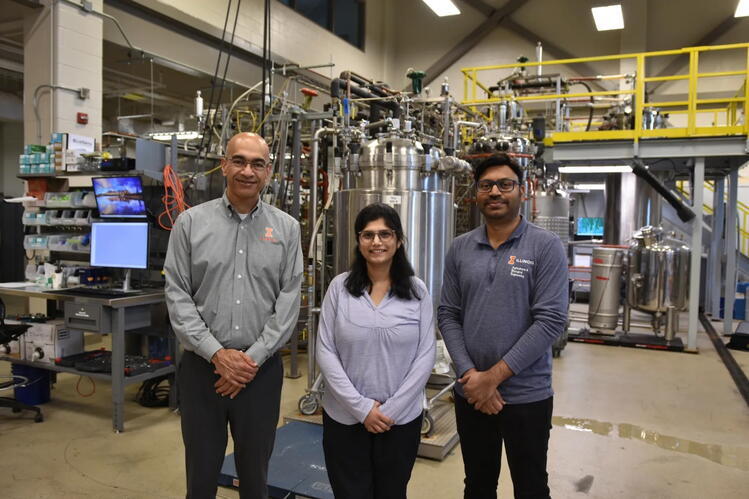

“We are evaluating the processing of CABBI crops at an industrially relevant scale, which will help commercialize biofuel and bioproducts production from these new crops,” said Vijay Singh, CABBI team lead on the study, CABBI’s Deputy Director for Science & Technology, Distinguished and Founder Professor of Agricultural and Biological Engineering (ABE), and Executive Director of the Integrated Bioprocessing Research Laboratory (IBRL) at the University of Illinois Urbana-Champaign.